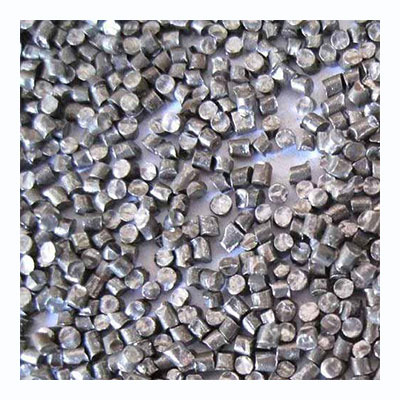

Stainless Steel Cut Wire Shots

??PREMIUM NON-FERROUS BLAST MEDIA FOR HIGH-PURITY SURFACE FINISHING

Overview

Stainless Steel Cut Wire Shots are precision-engineered blasting media produced from high-grade stainless steel wire (SS304 / SS430 / SS202 variants). Known for their?exceptional durability, rust-free operation, and contamination-free finish, these shots are the preferred choice for industries where surface cleanliness, brightness, and corrosion resistance are critical.

With controlled size, hardness, and conditioning, Stainless Steel Cut Wire Shots provide a?stable, repeatable blast profile?ideal for finishing stainless steel, aluminum, titanium, copper, and other corrosion-sensitive alloys.

- Description

Description

STAINLESS STEEL CUT WIRE SHOTS ?

PREMIUM NON-FERROUS BLAST MEDIA FOR HIGH-PURITY SURFACE FINISHING

Overview

Stainless Steel Cut Wire Shots are precision-engineered blasting media produced from high-grade stainless steel wire (SS304 / SS430 / SS202 variants). Known for their?exceptional durability, rust-free operation, and contamination-free finish, these shots are the preferred choice for industries where surface cleanliness, brightness, and corrosion resistance are critical.

With controlled size, hardness, and conditioning, Stainless Steel Cut Wire Shots provide a?stable, repeatable blast profile?ideal for finishing stainless steel, aluminum, titanium, copper, and other corrosion-sensitive alloys.

Key Features

1. Rust-Free, Contamination-Free Blasting

Being fully stainless, these shots do?not leave ferrous residues, ensuring:

? No rust streaks

? No staining

? No iron contamination on non-ferrous parts

Ideal for high-purity applications in?food processing, pharma equipment, surgical tools, auto components, cookware, and high-value stainless fabrications.

2. Extremely Durable ? Longer Life Than Cast Media

Cut from solid drawn stainless wire, these shots resist cracking and maintain shape for thousands of cycles, resulting in:

? Significantly longer media life

? Lower media consumption

? Minimal dust generation

? Reduced wear on blast turbines and nozzles

? Lower overall blasting cost

3. Uniform Finish on Stainless, Aluminum & Non-Ferrous Alloys

Stainless Steel Cut Wire Shots impart a?bright, satin-smooth finish?suitable for:

? Decorative stainless steel products

? Cookware and kitchen equipment

? Architectural fabrications

? Medical instruments

? Pump housings, valves, and machined components

4. Available in As-Cut & Conditioned (Rounded) Grades

- As-Cut:?Cylindrical, aggressive, high cleaning action

- Conditioned:?Spherical, uniform peening & decorative finishing

- Super-Conditioned:?Highest brightness & minimal roughness

5. Multiple Material Grades

Available in:

? SS 304

? SS 202

? SS 430 (ferritic)

? SS 410/420 (high hardness peening grades)

Applications

Stainless Steel Fabrication Industry

? Bright finishing of tanks, vessels, covers, trolleys

? Weld cleaning and blending

? Finishing of architectural SS sheets, railings, panels

Cookware & Kitchenware Manufacturing

? Uniform matte finish on stainless steel cookware

? Deburring and cleaning before polishing or coating

Automotive & Precision Engineering

? Cleaning & finishing of pump bodies, valves, turbine parts

? Surface refinement of machined components

? Non-ferrous component finishing without dimensional damage

Pharma, Food & Hygienic Equipment

? Contamination-free cleaning of stainless steel assemblies

? Satin finishing for hygiene surfaces

Aerospace, Defence & High-Value Components

? Controlled peening for fatigue life improvement

? Bright, non-contaminating finishing on titanium and aluminum

Technical Advantages

? Density: ~7.7 g/cm?

? Hardness: 40?55 HRC (customizable up to 58?60 HRC)

? Size Range: 0.20 mm to 3.00 mm

? Highly corrosion-resistant

? Low dust, high recyclability

? Stable and repeatable surface finish

Why Choose SYNCO Stainless Steel Cut Wire Shots?

- Manufactured from?prime-grade stainless steel wire

- Strict control on?size, hardness, tolerance & conditioning level

- Offered in?As-Cut, Partially Conditioned, Fully Conditioned & Super-Conditioned

- Zero iron contamination; ideal for finishing high-value components

- Supported by Synco?s end-to-end blasting solutions:

blast cabinets, pressure machines, wheel blast systems, recovery units, dust collectors, automation & robotic blasting

SYNCO guarantees consistency, performance, and supply reliability demanded by top manufacturing sectors worldwide.