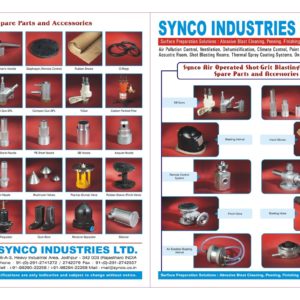

Nozzles

High-Performance Nozzles with TC & BC Inserts for Efficient Abrasive Blasting

SYNCO Blasting Nozzles?are precision-engineered for?maximum blasting efficiency, extended service life, and consistent abrasive flow. Designed for heavy-duty industrial applications, SYNCO nozzles are available with?Tungsten Carbide (TC)?and?Boron Carbide (BC)?inserts to suit different operating conditions, abrasives, and cost-performance requirements.

These nozzles ensure?optimal air velocity, uniform abrasive dispersion, and superior surface cleaning, making them a critical component of any professional blasting operation.

- Description

Description

High-Performance Nozzles with TC & BC Inserts for Efficient Abrasive Blasting

SYNCO Blasting Nozzles?are precision-engineered for?maximum blasting efficiency, extended service life, and consistent abrasive flow. Designed for heavy-duty industrial applications, SYNCO nozzles are available with?Tungsten Carbide (TC)?and?Boron Carbide (BC)?inserts to suit different operating conditions, abrasives, and cost-performance requirements.

These nozzles ensure?optimal air velocity, uniform abrasive dispersion, and superior surface cleaning, making them a critical component of any professional blasting operation.

Insert Options

?Tungsten Carbide (TC) Insert Nozzles

?Tungsten Carbide (TC) Insert Nozzles

SYNCO TC Nozzles?offer an excellent balance between?wear life and cost, making them ideal for general industrial blasting.

Key Benefits

- High resistance to abrasion

- Long service life compared to ceramic nozzles

- Suitable for steel shot, steel grit, garnet, copper slag, aluminum oxide

- Economical choice for continuous shop-floor use

Typical Service Life

- ~300?400 hours (depending on abrasive type & pressure)

Recommended For

- Fabrication shops

- Foundries

- Structural steel blasting

- Medium to heavy-duty blasting applications

?Boron Carbide (BC) Insert Nozzles

?Boron Carbide (BC) Insert Nozzles

SYNCO BC Nozzles?represent the?highest grade in blasting nozzle technology, offering?maximum wear resistance and the longest service life.

Key Benefits

- Extremely hard material (second only to diamond)

- Up to?3?5 times longer life than TC nozzles

- Maintains nozzle bore accuracy for longer periods

- Consistent blasting pattern and reduced air consumption over time

Typical Service Life

- ~800?1200 hours (depending on abrasive type & pressure)

Recommended For

- High-production blasting

- Continuous shift operations

- Expensive abrasives (garnet, steel grit)

- Critical surface preparation jobs

Nozzle Design Features

?Optimized Venturi Profile

?Optimized Venturi Profile

- Accelerates abrasive to higher velocity

- Improves cleaning speed

- Reduces air consumption per square meter

?Rugged Outer Jacket

?Rugged Outer Jacket

- Aluminum / polyurethane / rubber coated body

- Shock-resistant and operator-friendly

- Suitable for harsh site environments

?Consistent Abrasive Flow

?Consistent Abrasive Flow

- Uniform internal geometry

- Reduced turbulence and pressure drop

- Stable blasting intensity throughout nozzle life

Technical Specifications (Typical)

| Parameter | Specification |

|---|---|

| Insert Material | Tungsten Carbide (TC) / Boron Carbide (BC) |

| Nozzle Type | Long Venturi |

| Thread / Holder | Standard nozzle holders |

| Bore Sizes | 6 mm to 16 mm |

| Operating Pressure | Up to 12 bar |

| Compatible Abrasives | Steel shot, steel grit, garnet, copper slag, Al?O? |

Why Choose SYNCO Blasting Nozzles?

?Higher blasting productivity

?Higher blasting productivity

?Reduced air & abrasive consumption

?Reduced air & abrasive consumption

?Longer nozzle life = lower operating cost

?Longer nozzle life = lower operating cost

?Stable and predictable blasting performance

?Stable and predictable blasting performance

?Compatible with all standard blasting systems

?Compatible with all standard blasting systems

?Backed by SYNCO service & spares support

?Backed by SYNCO service & spares support

TC vs BC ? Quick Comparison

| Feature | TC Insert | BC Insert |

|---|---|---|

| Wear Resistance | High | Very High |

| Service Life | Medium-High | Maximum |

| Cost | Economical | Premium |

| Bore Accuracy Retention | Good | Excellent |

| Best For | General blasting | Continuous & high-end blasting |

Applications

- Portable air blasting machines

- Blast rooms & blast cabinets

- Shipyards & offshore structures

- Pipeline & structural steel preparation

- Foundries & heavy engineering

- Surface prep before painting & coating

SYNCO Quality Promise

Precision nozzles for consistent blasting results.

Every SYNCO blasting nozzle is tested for?dimensional accuracy, insert integrity, and performance, ensuring reliable operation in real industrial conditions.