Blasting Hose

Heavy-Duty Abrasive Transfer Solutions for Continuous Blasting Operations

SYNCO Blasting Hoses?are engineered for?safe, efficient, and long-life transfer of abrasive media?in air blasting and shot blasting applications. Designed to withstand?high abrasion, pressure, and impact, SYNCO hoses ensure?uninterrupted blasting performance?in the most demanding industrial environments.

Manufactured using?multi-layer reinforced construction, SYNCO blasting hoses deliver?maximum wear resistance, flexibility, and safety, making them ideal for both shop-floor and site blasting operations.

- Description

Description

Heavy-Duty Abrasive Transfer Solutions for Continuous Blasting Operations

SYNCO Blasting Hoses?are engineered for?safe, efficient, and long-life transfer of abrasive media?in air blasting and shot blasting applications. Designed to withstand?high abrasion, pressure, and impact, SYNCO hoses ensure?uninterrupted blasting performance?in the most demanding industrial environments.

Manufactured using?multi-layer reinforced construction, SYNCO blasting hoses deliver?maximum wear resistance, flexibility, and safety, making them ideal for both shop-floor and site blasting operations.

Key Features & Benefits

?Extreme Abrasion Resistance

?Extreme Abrasion Resistance

High-quality natural / synthetic rubber inner tube offers?excellent resistance to steel shots, steel grits, garnet, copper slag, aluminum oxide, and other abrasives, ensuring long service life.

?Heavy-Duty Reinforcement

?Heavy-Duty Reinforcement

Multiple layers of high-tensile textile / steel wire reinforcement provide:

- High pressure handling capability

- Resistance to kinking and collapse

- Stable performance under continuous blasting

?Flexible & Easy Handling

?Flexible & Easy Handling

Despite its rugged construction, SYNCO blasting hoses remain?highly flexible, reducing operator fatigue and improving maneuverability during blasting operations.

?Anti-Static & Safe Operation

?Anti-Static & Safe Operation

Conductive rubber lining dissipates static electricity, minimizing spark risk and ensuring?safe blasting in hazardous environments.

?Leak-Proof & Secure Coupling

?Leak-Proof & Secure Coupling

Precision-engineered hose ends allow tight clamping with blasting couplings, preventing air or abrasive leakage.

Typical Applications

SYNCO Blasting Hoses are widely used in:

- Air blasting & sand blasting operations

- Shot blasting machines

- Blast rooms & blast cabinets

- Portable blasting units

- Shipyards & offshore structures

- Steel fabrication & foundries

- Oil & gas pipeline surface preparation

Technical Specifications (Typical)

| Parameter | Specification |

|---|---|

| Inner Tube | Abrasion-resistant natural / synthetic rubber |

| Reinforcement | High-tensile textile / steel wire layers |

| Outer Cover | Wear-resistant, weather & ozone-resistant rubber |

| Working Pressure | 10?12 bar (varies by size) |

| Burst Pressure | ? 4 ? working pressure |

| Temperature Range | ?20?C to +70?C |

| Abrasive Media | Steel shot, steel grit, garnet, copper slag, Al?O? |

Available Sizes

- ID:?19 mm (??) to 50 mm (2?)

- Standard Lengths:?10 m / 20 m / 40 m

- Custom lengths available on request

Why Choose SYNCO Blasting Hoses?

?Longer Service Life = Lower Replacement Cost

?Longer Service Life = Lower Replacement Cost

?Consistent Abrasive Flow

?Consistent Abrasive Flow

?Safe Anti-Static Construction

?Safe Anti-Static Construction

?Rugged & Site-Proven Design

?Rugged & Site-Proven Design

?Compatible with All Standard Blasting Couplings

?Compatible with All Standard Blasting Couplings

?Backed by SYNCO Technical Support

?Backed by SYNCO Technical Support

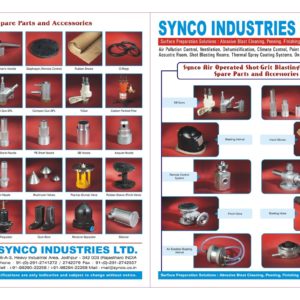

Optional Accessories

- Blast hose quick couplings

- Safety clips & gaskets

- Nozzle holders & blast nozzles

- Hose whips & clamps

SYNCO Quality Assurance

Designed to endure abrasion. Built for industrial reliability.

Every SYNCO blasting hose is tested for?pressure integrity, abrasion resistance, and dimensional accuracy, ensuring reliable performance in real-world blasting conditions.

| 3002140? ? ? ?? | SYNCO Blast Hose 1 1/4″ |

| 3001062 | SYNCO Blast Hose 1? |

| 3002119 | SYNCO Blast Hose 3/4″? |