Water-Wash Type Paint Booth with Integrated Curing, ETP & Motorised Trolley System

A Complete Surface Finishing Ecosystem for Modern Industries

Overview

The?Synco Water-Wash Type Paint Booth?is an engineered, end-to-end finishing solution combining?high-efficiency wet paint extraction,?controlled curing,?effluent treatment, and?motorised material handling. Built for environments where quality, safety, productivity, and environmental compliance are non-negotiable, this integrated system enhances coating consistency, reduces operator fatigue, and ensures 100% regulatory compliance.

It is ideal for automotive, fabrication, heavy engineering, furniture, OEMs, and component manufacturers seeking a clean, reliable, and streamlined finishing workflow.

- Description

- Reviews (0)

Description

A Complete Surface Finishing Ecosystem for Modern Industries

Overview

The?Synco Water-Wash Type Paint Booth?is an engineered, end-to-end finishing solution combining?high-efficiency wet paint extraction,?controlled curing,?effluent treatment, and?motorised material handling. Built for environments where quality, safety, productivity, and environmental compliance are non-negotiable, this integrated system enhances coating consistency, reduces operator fatigue, and ensures 100% regulatory compliance.

It is ideal for automotive, fabrication, heavy engineering, furniture, OEMs, and component manufacturers seeking a clean, reliable, and streamlined finishing workflow.

Key System Components

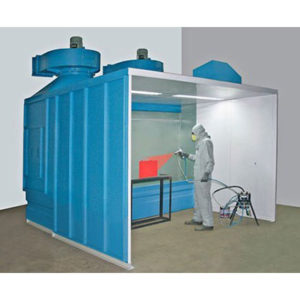

1. Water-Wash Type Paint Booth

- Two-stage or three-stage wet scrubbing for overspray capture.

- Eliminates fire hazards associated with dry filters.

- High booth luminosity for colour-accurate finishing.

- Fresh-air plenum and balanced draft ensure uniform airflow and dust-free coating.

- Stainless steel troughs and galvanised sheet construction for long service life.

- Suitable for solvent-based, PU, Epoxy, and specialised industrial paints.

2. Paint Curing Facility (Drying Oven / Curing Chamber)

- Optimised airflow pattern ensures uniform temperature across all zones.

- Fuel options: electrical heaters, gas-fired burners, diesel-fired systems.

- Digital temperature control (ambient to 150?C or as required).

- High-density insulation for faster heat-up and low heat loss.

- Increased throughput with reduced drying time and consistent curing.

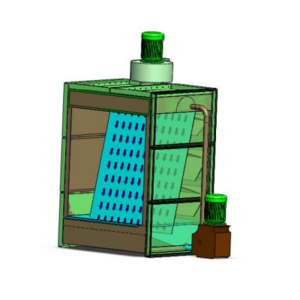

3. Effluent Treatment Plant (ETP)

- Treats booth water containing paint sludge and chemicals.

- Includes flocculators, settling tank, filter press, and sludge handling.

- Ensures safe discharge or recirculation of treated water.

- Compliant with Pollution Control Board norms.

- Reduces water consumption and supports green manufacturing practices.

4. Motorised Trolley System for Job Handling

- Heavy-duty motorised trolley designed for smooth, precise movement inside painting and curing areas.

- Can handle large, heavy, or elongated components.

- Runs on floor tracks or overhead rails depending on booth layout.

- Enhances material flow and reduces manual handling.

- Suitable for loads ranging from 1 ton to 50+ tons as per customer need.

Integrated Advantages

A. Superior Surface Finish

- Constant airflow and clean environment.

- Zero risk of dust and overspray contamination.

- Excellent paint transfer efficiency.

B. Higher Productivity

- Seamless movement from paint area to curing chamber using the trolley system.

- Faster drying ? quicker job turnaround ? higher daily output.

C. Environmentally Responsible

- Wet scrubbing technology reduces VOC and particulate emission.

- ETP ensures clean, compliant water discharge.

- Reduced waste generation and minimal environmental footprint.

D. Operator-Friendly & Safe

- Low noise blowers, ergonomic layout, and bright illumination.

- No fire hazard due to water-wash design.

- Controlled curing ensures temperature and solvent safety.

Applications

- Heavy engineering components

- Automotive parts and body shells

- Fabricated steel structures

- Electrical panels and enclosures

- Furniture and industrial fixtures

- Railways, defence, and aerospace maintenance

- Machinery and OEM production facilities

Optional Upgrades

- ATEX/Flame-proof motors for hazardous environments

- VOC-activated carbon filters

- Heat-recovery system for curing oven

- PLC/HMI-based automated booth control

- Water recirculation skid

- Stainless steel booth construction

- Multi-stage pre-filtration and post-filtration

Why Choose Synco

- End-to-end engineering under one roof:?booth + curing + ETP + trolley.

- Robust construction?for industrial environments.

- High safety standards?with flame-proof components available.

- Customised layouts?tailored to job sizes, production rates, and shop floor constraints.

- Strong after-sales support?with spares, service, and AMC.

Reviews

There are no reviews yet.