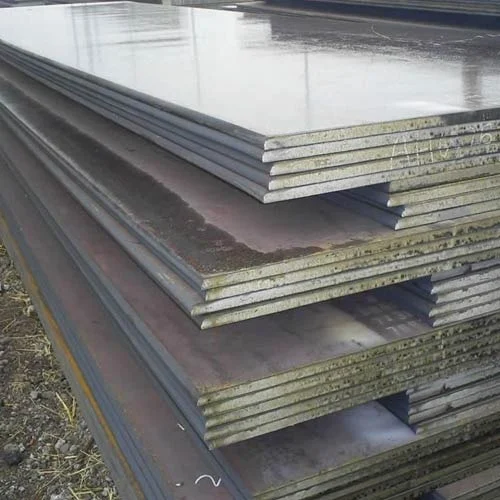

MN-13 Wear Resistant Steel Plates

SYNCO supplies Mn13 high manganese steel plates?are engineered?wear-resistant, austenitic steel products?designed for extreme abrasion, high impact, and heavy workload environments. With manganese content around?12?14%, these plates exhibit a unique?work-hardening effect: under impact or heavy load, the surface layer continually hardens to resist wear while the core maintains excellent?toughness and ductility?? delivering extended service life for critical components.

- Description

Description

SYNCO supplies Mn13 high manganese steel plates?are engineered?wear-resistant, austenitic steel products?designed for extreme abrasion, high impact, and heavy workload environments. With manganese content around?12?14%, these plates exhibit a unique?work-hardening effect: under impact or heavy load, the surface layer continually hardens to resist wear while the core maintains excellent?toughness and ductility?? delivering extended service life for critical components.

Key Features & Benefits

?Exceptional Wear Resistance

?Exceptional Wear Resistance

- High manganese composition forms a?hard surface layer (HB > 300)?during service through work hardening, significantly improving resistance against abrasion and impact.

- Outperforms conventional steels in high-stress environments where sliding and impact wear predominate.

?Superior Toughness & Impact Absorption

?Superior Toughness & Impact Absorption

- Even after work hardening, the internal structure remains?austenitic, retaining ductility and reducing the risk of brittle failure.

?Continuous Work Hardening

?Continuous Work Hardening

- Increased surface hardness with use results in?self-reinforcing wear resistance?? the more impact, the harder the surface becomes within limits.

?Versatile Processing

?Versatile Processing

- Suitable for?cutting, welding, bending, and fabrication?using standard industrial processes.

- Can be hot rolled, normalized, annealed, or finished to meet varied application specifications.

?Cost-Effective Life Cycle

?Cost-Effective Life Cycle

- Longer service intervals reduce?downtime, replacement frequency, and maintenance costs?compared with low-alloy steels.

Typical Applications

Mn13 plates are widely adopted across industries where wear and impact degrade component life:

- Mining & Quarry Equipment:?Crusher liners, mill liners, feeder housings

- Earth-Moving Machinery:?Excavator bucket teeth, dipper edges

- Material Handling:?Conveyor chutes, hoppers, screens

- Cement & Aggregate Plants:?Kiln parts, impact plates

- Construction & Heavy Fabrication:?Wear liners, protective plates

- Industrial Machinery:?Shredders, mixers, forging dies

Technical & Material Highlights

Chemical Composition (Typical)

- Manganese (Mn):?~12?14%

- Carbon (C):?~1.0?1.4%

- Silicon (Si):?~0.3?0.8%

- Phosphorus & Sulfur:?Very low for toughness and reliability

Performance Under Wear

- Starts at moderate hardness (~HB200?250) and work hardens to?>HB300?500?depending on impact intensity ? sustaining performance where conventional plates fail.

Competitive Advantages

?Work-Hardening Advantage:?Surface gets tougher during service, creating a dynamic wear barrier.

?Work-Hardening Advantage:?Surface gets tougher during service, creating a dynamic wear barrier.

?Impact Tolerance:?Excellent resistance to impact + abrasion synergy.

?Impact Tolerance:?Excellent resistance to impact + abrasion synergy.

?Versatile Fabrication:?Compatible with welding and machining for complex parts.

?Versatile Fabrication:?Compatible with welding and machining for complex parts.

?Extended Component Life:?Ideal for high-duty, high-wear environments.

?Extended Component Life:?Ideal for high-duty, high-wear environments.

Why Choose SYNCO / Partnered Mn13 Wear Plates

- Precision Engineered:?Manufactured to strict quality norms for consistent performance.

- Reliable Supply:?Available in multiple thicknesses and cut-to-size options.

- Technical Support:?Application guidance and material selection assistance.

- Cost-Superior:?Significant lifecycle savings versus lower grade alloys.

Ordering & Specifications

- Plate Thickness:?Available from?4 mm up to 80 mm?and beyond depending on requirement.

- Dimensions:?Custom widths and lengths as per project needs.

- Finish:?Hot rolled / processed to prevent surface defects prior to fabrication.

- Packaging:?Secure, export-ready packaging to preserve material integrity.

Applications & Industry Fit

| Industry | Typical Mn13 Uses |

|---|---|

| Mining & Quarries | Crusher parts, impact liners |

| Construction | Excavator components, bucket edges |

| Material Handling | Chute liners, screens |

| Cement & Aggregates | Kiln and ball mill liners |

| Heavy Fabrication | Wear plates, wear guards |