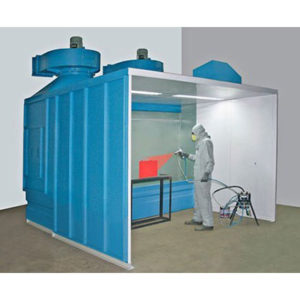

Semi Down Draught Paint Booth

Balanced Airflow. Superior Finish. Optimised Energy Consumption.

The?Semi Down-Draught Paint Booth?is engineered to deliver?high-quality paint finishes?while maintaining a?clean, controlled working environment?with lower installation and operating costs compared to full down-draught systems.

Designed for?automotive, heavy engineering, fabrication, structural steel, and industrial coating applications, this booth offers the?ideal balance between airflow efficiency and cost effectiveness.

How It Works

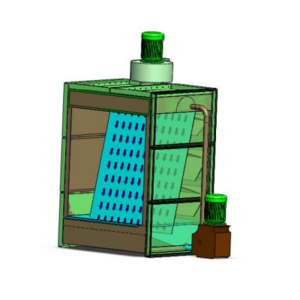

Fresh, filtered air is introduced from the?ceiling plenum?and flows?downward over the job, carrying overspray and solvent vapours away from the painted surface. The air is then extracted through?rear or side exhaust filters, creating a controlled semi-vertical airflow pattern that minimises paint defects and improves coating uniformity.

- Description

Description

SYNCO Semi Down-Draught Paint Booth

Balanced Airflow. Superior Finish. Optimised Energy Consumption.

The?Semi Down-Draught Paint Booth?is engineered to deliver?high-quality paint finishes?while maintaining a?clean, controlled working environment?with lower installation and operating costs compared to full down-draught systems.

Designed for?automotive, heavy engineering, fabrication, structural steel, and industrial coating applications, this booth offers the?ideal balance between airflow efficiency and cost effectiveness.

How It Works

Fresh, filtered air is introduced from the?ceiling plenum?and flows?downward over the job, carrying overspray and solvent vapours away from the painted surface. The air is then extracted through?rear or side exhaust filters, creating a controlled semi-vertical airflow pattern that minimises paint defects and improves coating uniformity.

Key Advantages

?Improved Paint Finish

?Improved Paint Finish

- Semi down-flow pattern reduces?dust settlement, dry spray, and paint bounce-back

- Uniform airflow ensures?consistent film thickness and gloss

?Operator-Friendly & Safe

?Operator-Friendly & Safe

- Continuous removal of?overspray and VOC-laden air

- Better visibility and breathing conditions inside the booth

?Energy & Cost Efficient

?Energy & Cost Efficient

- Lower air volume requirement than full down-draught booths

- Reduced fan power and heating load

- Ideal where?floor excavation is not feasible

?Flexible & Scalable Design

?Flexible & Scalable Design

- Suitable for?small components to large fabricated structures

- Can be supplied as?drive-in type, trolley-mounted jobs, or crane-loaded applications

Standard Construction Features

- Robust?MS fabricated structure?with industrial-grade powder coating

- High-efficiency?intake pre-filters and ceiling fine filters

- Multi-stage?exhaust filter system?for overspray capture

- High-capacity centrifugal fans with low noise operation

- Flameproof LED lighting with uniform lux distribution

- Easy-access filter replacement and maintenance panels

Optional Add-Ons

- Paint curing / baking system?(Diesel, Gas, LPG, or Electric)

- VFD-controlled fans?for energy optimisation

- VOC control systems?(Water scrubber / Activated carbon)

- Motorised trolley or rail system

- PLC-based control panel with safety interlocks

- Heat recovery unit for reduced operating cost

Applications

- Automotive body and component painting

- Heavy fabrication & structural steel coating

- Agricultural and construction equipment

- Industrial machinery and enclosures

- Defence, railways, and infrastructure projects

Why Choose a Semi Down-Draught Booth?

When you need?near-down-draught paint quality?without the?civil cost and energy load?of a full down-draught system, the?Semi Down-Draught Paint Booth?is the most practical and proven solution.